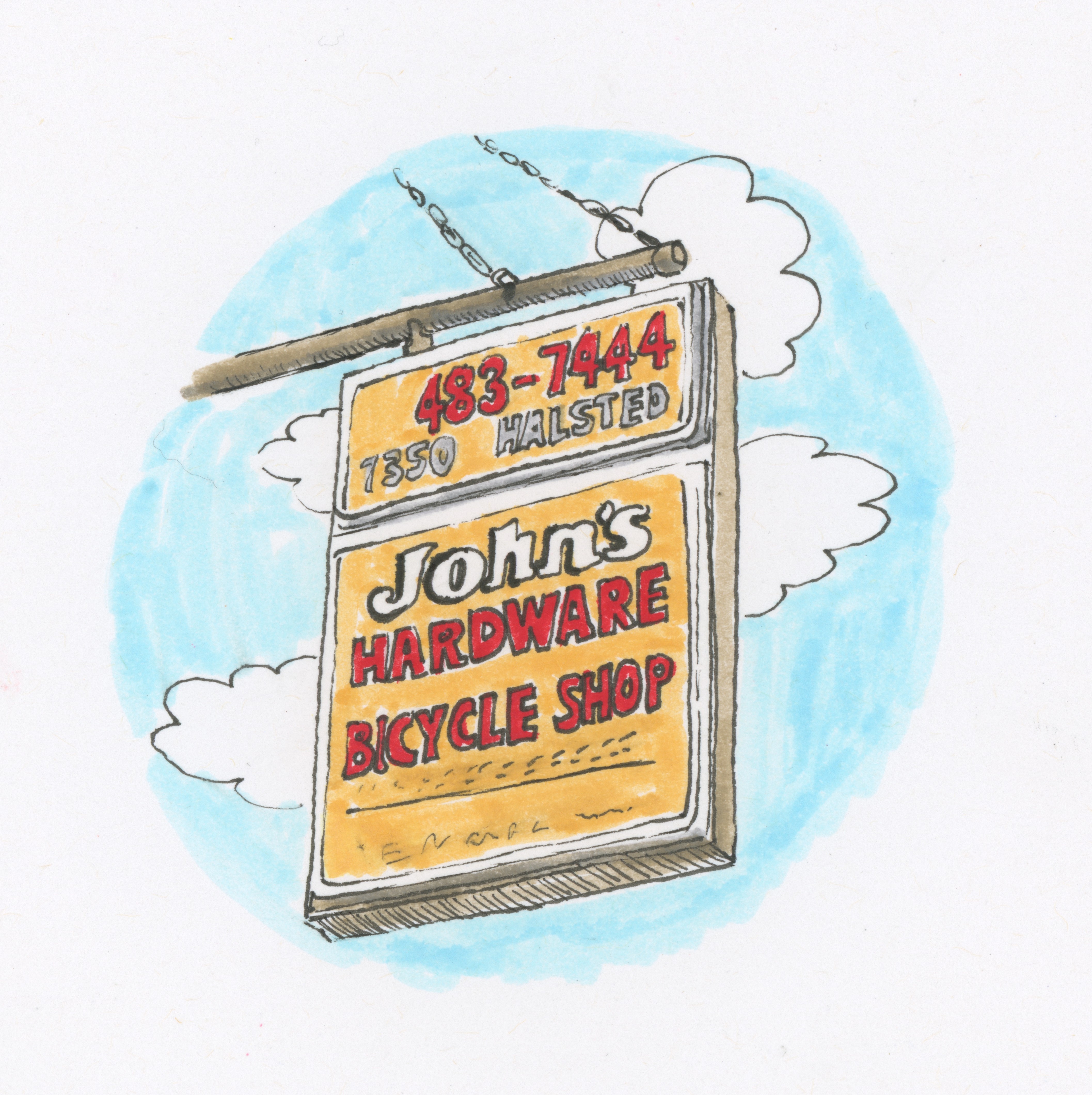

John Stallworth has been selling hardware and fixing bikes at his shop on Chicago’s South Side for 50 years, helping to anchor a neighborhood that’s struggled with population loss and divestment. John’s Hardware and Bicycle Shop is the kind of old-fashioned business that’s happy to sell customers two nails instead of a whole box. The store’s motto is “If we don’t have it, you don’t need it.” Today more than ever, the neighborhood needs John Stallworth and his business.

Transcript

WAILIN WONG: A couple months ago, John Stallworth had a customer show up at his hardware store on Chicago’s south side.

JOHN STALLWORTH: He came in and wanted a key made. The key is a dollar seventy five cent. We don’t take a credit card for less than ten dollars, so he says, “I don’t have no cash, I don’t have no cash.” I said, “Take the key and bring me my money back whenever you in the neighborhood.”

WAILIN: John’s Hardware and Bicycle Shop has been open since 1952, and it still operates with the mentality of an old-fashioned neighborhood store where the owner trusts his customers to come back with the money they owe him. For John Stallworth, it’s not about nostalgia or charity. It’s good business sense.

JOHN: You got to, you know. If you don’t trust, and mainly for a small amount like that, I mean, it’s a plus on both hands. If I make the key, and if I don’t let him go with the key, there’s nothing I can do with the key. The key’s already made. So my chances of him bringing it back and making him a better customer is let him go ahead with a dollar and seventy five cent and really he came back and he really thanked me for it, so I know he’ll be back. I know he’ll be back.

WAILIN: Welcome to The Distance, a podcast about long-running businesses. I’m Wailin Wong. On today’s show, the story of a hardware store that helps keep its neighborhood together — literally, in some cases, and also in less tangible but crucial ways. The Distance is a production of Basecamp. The brand new Basecamp 3 helps small business owners stay in control of projects and reduce email clutter. Tasks, spur of the moment conversations with coworkers, status updates, reports, documents and files all share one home. And now your first Basecamp project is completely free forever. Sign up at basecamp.com/thedistance.

JOHN: This store opened in 1952 under a gentleman by the name of Hank and at that time, of course I was just a little, small kid. But when I started working, my first job was I was working for uh a small, real small hardware store and he was so small that many times he had to send over here to buy inventory to be able to take back and sell. I used to take my bike and come over here and buy different products for him to take back, so one day Mr. Hank asked me did I like to work for him and I started working for him at 17 years old. I told him that, you know, I can fix bikes and he says okay, come on. So we start just doing tube changes and stuff like that. I worked for Hank from that point up until 1969, when Martin Luther King got killed and then his wife and his family said, “We gotta move, we gotta get out of here.”

WAILIN: Hank wanted John to take over the store, but he didn’t offer any financial help. When John applied for a loan through the Small Business Administration, he got turned down because he couldn’t put up enough collateral. That’s when the owner of a nearby grocery store, who had known John since he was a child, stepped in to help.

JOHN: I always felt that I should be in the business. I loved it. It’s something that I wanted to do all the time, but at that point I didn’t realize that I needed money to be able to do inventory and when we finished with the loan and everything, I didn’t even have money to buy my license, so the guy that put the store up for collateral, he loaned me starting-up money, he loaned me, you know, to get my license and all of that.

WAILIN: John’s Hardware and Bicycle Shop is located in the south side neighborhood of Englewood, where John has spent his entire life. When he took over the store in 1969, Englewood had a vibrant retail district at the intersection of 63rd Street and Halsted, not far from John’s shop. He remembers competing with seven to 10 other hardware stores in the area. John prided himself on having the best selection and service. The store’s long-time motto is: If we don’t have it, you don’t need it.

JOHN: We came up with that probably when I first opened, 1969, and uh I had a customer come in, says “You know, every time I come in here, you got what I need. That’s why I say I always go to John. He got it, he got it.” So I said at that point, I need a slogan. So I said, “If we don’t have it, you don’t need it” and I been using that ever since.

WAILIN: John’s competitors slowly faded away over the decades, leaving him as the lone independent hardware store and bike shop around for several miles.

JOHN: I’m probably the oldest black hardware in the city, period, you know, and at one point I had a lot of competition with hardwares. Not black, but just hardware in general and they all closed down. We had a True Value, we had an Ace, you know, and they all gone and I’m still here.

WAILIN: There were other economic forces at work in Englewood. The development of nearby shopping centers drew traffic away from the retail district around John’s store. The neighborhood, which decades earlier had attracted middle class African American families, started to suffer from foreclosures, population loss, poverty and crime.

JAMAL JULIEN: I grew up in Chicago, on the south side, and, you know, the Chicago that I grew up in, is substantially different than the Chicago that exists today.

WAILIN: That’s Jamal Julien. He went to high school in Englewood and he’s the co-founder of Slow Roll Chicago, an organization that uses the bicycle as a literal vehicle for social change. They organize bike rides through neighborhoods on the city’s south and west sides, where infrastructure like bike lanes and access to bikes lags behind the more affluent north side. In Jamal’s view, cycling is closely linked with not just individual health and recreation, but sustainable economic development.

JAMAL: If the community is walkable and bikeable, that means that there’s a local grocery store that I can patronize. There’s a local restaurant that I can patronize. The school is in close proximity and so that’s, that’s a different type of living. You know, if everything is outside the community, that means the community doesn’t have a tax base and the tax base is what drives or funds infrastructure projects. That’s what funds education and so we need a lot of these resources to be in the community so that the communities are healthier and more sustainable.

WAILIN: John knows how important the bike repair services are both to the neighborhood and to the future of his business.

JOHN: Bike is one of the things that keeps me afloat now ‘cause when the first store that came along was a Home Depot and he put a hurt on me, and then the Lowe’s came along and they put a hurt on, and now is Menard’s is all right here in my same little area, so it ended up being more of a bike shop than anything. I was selling bikes at that point but then the Walmart came in and the bikes that they sell was, you know, too cheap and I couldn’t compete because I didn’t believe in selling a real cheap bike, so then I ended up stop selling bikes. Total repair now, service, that’s all I do for bikes, yeah. I had one guy, he brought his bike in and I told him it’d be a couple days before he could get it. He said, “No, that’s my transportation to work. I gotta have my bike.” My son and I, we close at six. We was here until eight o’clock fixing bikes because people said they needed their bikes, so I don’t mind staying over, you know, and fixing them.

JAMAL: If I’m in Englewood or if I’m in Roseland or Chatham or any of these communities that have suffered severe divestment and reallocation of resources and things like that, well, if I’m a kid, where do I go get air in my tires? Even things like that. Like when I was a kid, you’d go to the bike shop or you’d go to the gas station and you’d get air in your tire. And now the air costs a dollar fifty, two dollars and it used to be free, you know, so if I’m low to moderate income, I can’t afford some of these things.

WAILIN: It’s difficult for John to compete with the big hardware chains on price, so he puts his effort into service, whether it’s extending his store hours, letting a customer pay for a key later or spending extra time to troubleshoot a problem in someone’s home.

JOHN: When I said service, I still will sell ’em two nails if they want two nails. Home Depot you gotta buy the whole package. Realistic, you make as much if not more money because for one screw you can sell it for a little bit more. A person willing to pay you 50 cents for a screw, but they don’t need a whole package that they got to pay two dollars for, you know, so it works out. I’m able to tell ’em how to fix what they need fixing and Home Depot can’t do that and the Menards. With these modern cameras and stuff, they bring in a picture and says, “I got this here and I don’t know how you should do it.” And most of the time, I’m able to look at it and determine what they got going on. I had a guy last week, he came in and says, “I got a, uh, leak coming in from this wall, you know, I’m not sure where it’s coming from.” And I looked at the picture and I said, “That’s got to be a foundation leak” because they said it only happens when it rains.

WAILIN: John Stallworth Junior, who goes by Johnny, has put his own spin on his father’s customer service. Johnny attended college in Louisiana and ended up staying down south for 16 years. When he returned to the family business around 2004, he introduced a touch of southern hospitality, something he had observed at Walmart stores in Louisiana.

JOHNNY: When I first came back, you know, I tried to greet everyone when they come in the door, you know, let everybody know “Hey you here, we recognize you, we might be a little minute getting to you but if you just be patient, we’re gonna take care of you.” You know, and the more comfortable they are, the more they’ll shop, you know. A lot of times, customers will say, “Hey look man, let me get up out of here because I’m gonna find something else to buy.” Hey, take your time, you know, buy as much as you like.

WAILIN: Johnny’s been working at the store since he was a child because his father always said when you’re old enough to walk, you’re old enough to work. Today, he handles the retail store while his father oversees a general contracting business, which was started in 1977 after an electrical fire destroyed the shop.

JOHN: The fire department called me. I was at home in the bed and then came down and couldn’t do anything but stand across the street and look at them putting the fire out. It was a sad day. I had insurance but the insurance was not sufficient to put the business back together. So at that point I said, “Well, I can put it together myself,” so I started a contracting business in 1977 and I put my business back together, and from that point when I been doing my own construction also. In a way, it was a blessing because I was able to expand. I went all the way to the alley. I ended up with probably another 600 square feet of space, so it worked out real good.

JOHNNY: He got with some friends that really helped out. Everybody pitched in and they got it back up and running. That situation, even though I was young then, um, that situation there kind of put in my mind that maybe I don’t wanna work for anyone else neither, you know, I wanna do my own thing.

WAILIN: The contracting business does small fix-it jobs all the way up to larger-scale building projects, and John gets a lot of customers and referrals from his church, where he’s a deacon. Between the contracting, the hardware store and the bike repair, the Stallworths run a business that’s essential to the health and future of their neighborhood. Their customers are looking to fix up their homes or businesses, or build new ones. They need bikes to get to work, for exercise, or for their kids. The continued survival of John’s Hardware and Bicycle Shop is a bulwark against economic blight and a beacon for other Englewood residents working to improve the neighborhood. Here’s Jamal Julien of Slow Roll Chicago.

JAMAL: If we create this perception that it’s crime-filled, it’s dangerous, it’s violent, once the local proprietors close, no one is gonna be attracted to come in. And so if somebody like John were to close, it’s over. It would totally be over. Nobody’s gonna go in there to fill that void, that space that he’s holding down right now. What we would have is John’ll close down and then you know, everybody will have to go to the Lowe’s or the uh, the uh, I call it Homeboy Depot, you know? And, and that money is never gonna return to the community.

WAILIN: Johnny sees encouraging signs in Englewood. A Whole Foods is about to open, and some locally owned businesses are popping up too. If people return to Englewood, reversing decades of population declines, the Stallworths will be there to help them with their homes.

JOHNNY: You’re providing a service to the community that’s like everyday living, they have to deal with it, you know, whether you’re renting, whether you’re at home, there’s always something breaking at the home, whether there’s a flush lever, uh, whether it’s a sink knob and it’s those small inconvenience that if you can provide that product for the customer, then they’re happy. Same way with the bike business, if you can get a child at a young age, bike breaks down, they’re disgruntled, you know, their parents and them come in and look, my bike is in this condition and I want to ride. And when you repair that bike, it makes that child so happy, you know, and a lot of times they don’t forget that. They get older and they know “Hey look, I remember this bike shop when I was a kid, they took care of me so now I’m an adult, they still take care of me.” So it’s just the fact of helping people with everyday living.

WAILIN: John Senior has no plans to retire. After our interview, I was on the expressway going home when I spotted the van for the Stallworths’ contracting business in the next lane. I peeked over and there he was in the driver’s seat, heading to another job.

JOHN: I love what I do. That question was just asked to me the other day by one of my contracting customers and uh she buy a lot of condo units in this building and she uses me to do all of her work and she asks me, she says, “John, how old are you?” I said, “I’m 70.” “How much longer you gonna be working?” I said, “Until the Lord calls me home.” She said, “Be realistic, because we want to buy these condos but no one know nothing, so you fix everything and if something happened to you, we don’t know what we gonna do.” You know, I enjoy what I do, as long as my health let me, I’m gonna keep going.

WAILIN: The Distance is produced by Shaun Hildner and me, Wailin Wong. Our illustrations are done by Nate Otto. You can listen to all our previous episodes at thedistance.com, on iTunes, Google Play Music, Stitcher or wherever you get your podcasts. We’d also love it if you could rate and review our show on iTunes so we can climb those charts and get discovered by new listeners. The Distance is a production of Basecamp, the app for helping small business owners stay in control of projects and reduce email clutter. Your first Basecamp project is completely free forever. Try the brand new Basecamp Three for yourself at basecamp.com/thedistance.