The Distance is back from our brief hiatus with a new episode that you should listen to while eating a huge stack of pancakes or waffles. The Funk family of Funks Grove, Ill. has been boiling maple tree sap into syrup for nearly 200 years — at first because it was the only readily available sweetener in this newly settled patch of central Illinois, and more recently as a commercial operation. The acres of maple trees in Funks Grove, along with syrup-making expertise and the love of a business that’s unpredictable and laborious, are family assets that have sustained generations of Funks.

Also, the Funks spell syrup with an I—their business is called Funks Grove Pure Maple Sirup. You should listen to the episode (or scroll down for the transcript) to find out why. And lest you think “sirup” is a made-up spelling, I did confirm its existence in my husband’s compact edition of the Oxford English Dictionary. It comes with a little magnifying glass in a drawer and makes me feel like a old-fashioned lady detective. But I digress. On with the story!

Transcript

WAILIN: The first thing you should know about Funks Grove Pure Maple Sirup is that syrup is spelled with an I. That’s S-I-R-U-P. It’s an old-fashioned spelling of the word and the one preferred by Hazel Funk Holmes, the woman who built a business in the 1920s selling maple syrup from her family’s trees in central Illinois. According to the Funks, syrup spelled with an I was how Webster’s referred to the stuff that comes from boiling sap, with no added sugar. This spelling was so important to Hazel Holmes that she specifically mentioned it in her trust.

MIKE FUNK: Mrs. Holmes was really a stickler for that, that that was maintained, and we’ve had sign companies repaint our signs sometimes and say “Oh, you misspelled syrup,” so they would spell it with a Y, and we’d have to send it back and say, “No, it’s not gonna work.”

WAILIN: That’s Mike Funk, who is the fifth generation of his family to make maple syrup on the family land in Funks Grove, Illinois, about 150 miles south of Chicago. Mrs. Holmes was Mike’s grandfather’s cousin, and the arcane spelling of syrup isn’t the only thing she enshrined in her trust. She also made sure that the family’s timber and farmland would be preserved for future generations to keep producing maple syrup and making a living from it. In the decades since then, generations of people driving on Route 66 have stopped in for a taste of the Funks’ syrup.

MIKE: We have a business that’s on Route 66 since Route 66 became Route 66, back in the 1920s. Uh, we’ve kind of worked hand in hand. They had a nice four-lane highway between Chicago and St. Louis traveling by our front door, so I don’t know what could be better than that, as far as getting exposure. Once people try the syrup and they feed it to the kids and they get hooked on it, then we get kind of a multi-generational thing going here so it’s been a really, really fortunate thing for us.

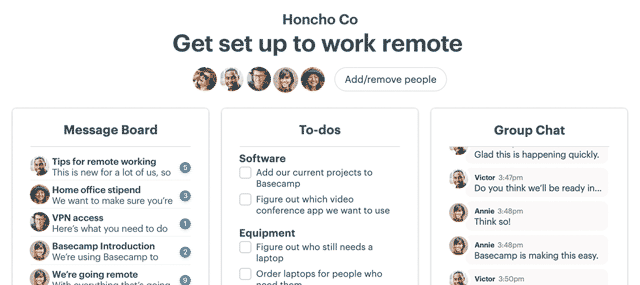

WAILIN: Welcome to The Distance, a podcast about long-running businesses. I’m Wailin Wong. On today’s show, the story of the Funk family and the 400 acres of maple trees that have sustained it. The Distance is a production of Basecamp. The brand new Basecamp 3 is everything any team needs to stay on the same page about whatever they’re working on. Tasks, spur of the moment conversations with coworkers, status updates, reports, documents and files all share one home. And now your first basecamp is completely free forever. Sign up at basecamp.com/thedistance.

MIKE: Maple syrup production is something that you have to really enjoy it to keep doing it because it’s a very, uh, laborious process. You’re real excited when the season first starts and after about four weeks, you’re ready to throw it all in because you’re getting tired from watching the sap boil.

WAILIN: Not only is maple syrup production incredibly labor intensive, but it’s also unpredictable. Mike and his wife, Debby, start each season without knowing exactly when they’ll have syrup to sell. Usually it’s around March, but it depends on what the weather has been like during the winter. If you want Funks Grove Pure Maple Sirup, you have to call, check their website or check the sign hanging at the end of the farm’s driveway to see if syrup is on sale yet. Maple syrup is all about good timing, something Mike has learned from a lifetime in the business, starting from when he was eight years old, collecting sap in his own small buckets and pouring it into milk cans by the side of the trail for his parents’ crew to pick up.

MIKE: In January, you’re watching the weather very closely to see when it’s, when the temperature’s gonna start to get above freezing where you can go out and tap, so you’re looking at long-range forecasts. Because sometimes, our season will start in early February. Sometimes it won’t start until early March because we just don’t know when that warmth is gonna come.

WAILIN: Sap is stored in the trees’ roots during the winter. When the temperature gets above freezing during the daytime, sap flows to the branches, carrying sugar and minerals. The sap then recedes at night, when the temperature drops below freezing. Mike and his crew are looking for a consistent cycle of thawing and freezing, with temperatures in the 40s during the day and the 20s at night. When that happens, they can start tapping.

MIKE: In the olden days, as we say—as old people always say—we always thought, or were told by the experts that a cold, cold winter gave you sweeter sap. Well, we find out that that’s not really true. It’s more, uh, a nice growing season for the tree, the more photosynthesis that it can accomplish, the more sugars it makes through that process, so we’re looking for trees that aren’t stressed, trees that have the water they need, have the sunlight they need, and so they’re gonna produce those sugars and they’re gonna be healthy.

WAILIN: Climate change has been an increasing source of concern for maple syrup producers, including Mike and Debby, and now their son Jonathan and nephew Sean, who are partners in the business. Warmer winters are bad for sap production and, over the long term, could make this part of the country inhospitable to maple trees.

MIKE: We’ve thought for years that—and I’ve read articles—that well, in 40 years or 50 years, the opportunity to make maple syrup is going to keep moving north. Well, we haven’t really seen that yet, but so maybe it’s not gonna happen as fast as we think or maybe, you know, in 20 years, we’ll see a big effect. We really, we really don’t know.

Sound of driving

WAILIN: Are we here?

JONATHAN FUNK: We’re here.

WAILIN: That’s Jonathan Funk, Mike and Debby’s son. He’s going out to tap some trees. The Funks own about 3,500 maple trees that get tapped every year. Trees have to be 12 to 16 inches in diameter before they’re ready to be tapped, and it takes about 40 years to get to that size. After that, trees will give sap for their entire lives as long as they stay healthy. The Funks are careful not to overburden their trees. Years ago, they might have put three to four taps in their largest maples, but today, that’s down to one or two.

JONATHAN: You look at the old tap marks and you try and find the best distance from the old tap. We typically move over about 2 inches and then 4 inches up or down from the last tap.

Sound of drilling

WAILIN: Jonathan uses a gas-powered drill to make holes that are about an inch and a half deep. Then it’s time to hammer in the spouts. Here’s Debby.

DEBBY FUNK: At the end of the season we pull the spouts out and those holes will heal in a matter of weeks. And then when they heal, it leaves scar tissue and so the next year, when the sap is moving up, sap moves in the wood right under the the bark of the tree, and so it’ll divert around the scar tissue. So if you tapped into an old tap hole, you wouldn’t get any sap out of that spot, so that’s why each year, you have to tap a different spot on the tree.

WAILIN: With the spouts in place, sap starts dripping into the metal bucket. Temperature, sunlight and barometric pressure all make a difference in how quickly the sap flows.

Sound of dripping

MIKE: I’d say our target is usually about a hundred thousand gallons of sap in a year and then we know we’ll have a really good gallons of syrup made. It’s a 40-to-1 ratio of sap to syrup so our best year recently was about 3,000 gallons of syrup so it took well over a hundred thousand gallons of sap to do that.

WAILIN: The Funks use buckets for half of their trees. For the other half, they’ve installed a more modern tubing system where sap is pulled through plastic lines that ultimately feed into a large tank. In other maple syrup-producing states like Vermont, the trees grow on hillsides so the sap flows on its own through the tubes. Illinois is very flat, so the Funks have to use a pump system to gently suction the sap into the tank. Whether they’re using buckets or tubes, the Funks have to move fast to get the syrup made. They try to boil all of the sap on the day it’s collected because sap spoils easily in warm temperatures.

Sound of evaporator

WAILIN: That’s the sound of the Funks’ 260-gallon evaporator, which sits in their sugar house. It’s a shiny, stainless steel, Canadian-designed machine that the Funks bought secondhand and are using for the first time this season. The sap that comes out of the tree is watery, colorless and only faintly sweet. The key to making pure maple syrup is to boil sap until the sugars caramelize, producing that thick, rich, amber-colored liquid.

MIKE: It developed gradually from, uh, a cauldron over an open fire, just adding sap as it steamed off. Later they found out they could start another smaller pot. They would pour in some of the sap that was more advanced or thicker and then they’d start another pot of just the raw sap. Eventually they went to three pots over three different fires and would move it from one to one until they got to the finishing point and now today’s evaporators basically do the same thing, where it’s a continuous flow from sap at the very beginning and as it flows through it gets thicker and thicker to where you draw off at the end, so you still have the three cauldrons, but they’re connected now.

WAILIN: It takes an hour and a half for the sap to travel from one end of the evaporator to the other. During the process, the liquid goes from about 2 percent sugar to 66 percent sugar. The Funks are looking for a final temperature of 219 degrees Fahrenheit, or 7 degrees higher than the boiling point for water. Nothing is added during the process. In an age of overhyped artisanal comestibles and myths around all-natural food, the Funks’ operation is refreshingly straightforward.

MIKE: Really, how can you beat that? And you don’t have a big long list of ingredients on the label, so it’s a very natural product and, uh, people are very aware of stuff like that nowadays.

WAILIN: The Funks let the syrup cool and bottle it in the back room. That’s usually when Mike tastes his syrup for the first time.

MIKE: Early in the season, you may only have light syrup in the beginning because when the sap is really sweet, the boiling time’s a little less, you get less caramelization and so a lighter flavor. Some people really like that and they’ll come to buy early in the season because they know that’s when it’s made and then people that like the really dark will say, “I’ll wait until the end of the season because I know that’s when the dark is made.”

WAILIN: Debby makes the call on when to open the shop, which is just steps away from the evaporator room where you can breathe in the buttery aroma of caramelizing sugar. It’s usually around March first, and the Funks tend to sell out by the end of August or early September. This year, a quart of Funks Grove Pure Maple Sirup costs 18 dollars and a half gallon is $32.

MIKE: Mrs. Holmes always wanted us to at least adhere to what it would cost to have maple syrup shipped from Vermont to here, so as long as we were within, in that range, and we’ve always been able to stay pretty close.

WAILIN: When the season ends, there’s just a few months of cleaning, maintenance and other prep until the weather gets cold again and it’s back to figuring out when the next season will start.

Mike has always been drawn to these woods. He went to college, thinking he would become an accountant, but left school after a few semesters to return to the family farm. He’s continuing an agricultural tradition started by his ancestor, Isaac Funk, who founded Funks Grove in the 1820s and was a farmer, state lawmaker and friend of Abraham Lincoln’s. Today, if you drive through Funks Grove, you’ll find a nature center, museum, historic chapel and a small cemetery. And, of course, you’ll see the family’s famous maple trees.

MIKE: A lot of Funks Grove timber is virgin timber that was never cleared and we thank our ancestors for that—for not clearing all the trees off to farm, so it’s very nice to have a lot of woodland areas that look like they did maybe a couple centuries ago.

WAILIN: The Distance is produced by Shaun Hildner and me, Wailin Wong. Our illustrations are done by Nate Otto. You can find us at thedistance.com, on iTunes and you can also now subscribe to our show on Google Play Music. The Distance is a production of Basecamp, the leading app for keeping teams on the same page about whatever they’re working on. Your first Basecamp is completely free forever. Try the brand new Basecamp Three for yourself at basecamp.com/thedistance.