Tim Masters describes himself as “just a mattress maker,” but that belies the business acumen he’s gained over decades of building and selling beds. Tim’s store in the Chicago suburbs, Quality Sleep Shop, opened in 1969 and has held its own against the proliferation of private equity-backed mattress corporations and chain stores. As Big Mattress has grown more complex, churning out endless permutations of confusingly named products, Tim has embraced simplicity.

Transcript

WAILIN WONG: Hi everyone, it’s Wailin. We have some news about The Distance that we’ll share at the end of this episode, so please stick around for that. And here’s today’s show.

Think about some of the most miserable experiences you’ve had as a consumer. You might say air travel, or trying to cancel your cable service. And then there’s mattress shopping. Where I live, in the Chicago area, there seem to be mattress stores on every corner, sometimes across the street from each other, and they’re selling products with long names that make it difficult to comparison shop. Like “Simmons Beautyrest Recharge Signature Select,” which is somehow different from the “Serta iComfort Blue Max Touch 3000.”

TIM MASTERS: They’re showing you beds like two, three thousand dollars and it’s like, what makes that bed cost two or three thousand dollars? I don’t know. I look at ’em and I think, that’s not a two or three thousand dollar bed. And then they walk you down from there, but I think it’s by design that they want you to be a little bit confused, overwhelmed or impressed with this lingo that you don’t even know what it stands for.

WAILIN: That’s Tim Masters, the owner of a store in the Chicago suburbs called Quality Sleep Shop. He’s been a mattress maker for over 25 years, and he’s not a fan of the tactics you see from traditional, corporate mattress manufacturers and stores.

TIM: I wouldn’t want to be in the market to buy a mattress today; I’ll tell you that. I’m keeping it simple, like there’s not that much to it. It’s soft, medium, firm. What’s your price point, is it low, medium or high? We try not to confuse you.

WAILIN: Welcome to The Distance, a podcast about long-running businesses. I’m Wailin Wong. On today’s show, how Tim Masters has fended off the big mattress companies by staying small, simple and honest.

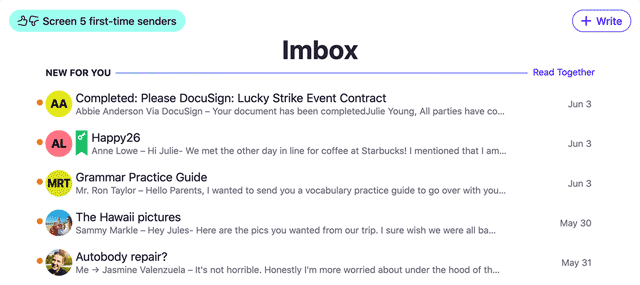

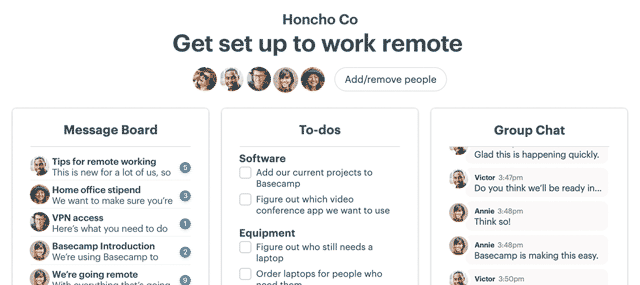

JASON: The Distance is a production of Basecamp. I’m Jason, an iOS designer at Basecamp. Basecamp is the better way to run your business. It’s an app for communicating with people and organizing projects and work. If you’re feeling overwhelmed by email, chat and meetings, give Basecamp a try. Sign up for a 30-day free trial at basecamp.com/thedistance.

TIM: Every year, I buy the best seller of that year and I take them apart and I dissect them, like how was this made, like how far apart are the stitches, what are they doing, how are they securing their cover, what filling material are they using, why is this bed so popular? Is there anything I can make similar or what can I improve on with it? And in 2014, I bought a Tempur-Pedic. I paid $1,630 for this twin size bed but it was a best seller and I’m so excited. I go pick it up and I bring it back to the shop, I’m like, here it is and I get the thing apart and I was so deflated, like it had an nice like one-inch piece of memory foam on top and had three inches of actually really nice quality foam under that, but the supporting foam, the six-inch supporting base, is like a general grade. And I was so, I’m bothered by it because I’m like, why would they have such a good company, you know what I mean? Such a good name, and then fill it with just like average or below average filling material? You’re gonna hurt your brand. And it’s like, I don’t think they get it and I see that a lot with the major brands. It’s like, don’t you get it? It doesn’t have to just look pretty on the outside. It’s got to be the inside of the bed that counts.

WAILIN: So what’s inside a bed? Tim makes both innerspring mattresses and latex ones, and he uses a combination of cotton and foam. Cotton breathes well, lasts a long time and wicks away perspiration. Foam is pressure relieving and more lofty, giving the impression of a thicker mattress. At Tim’s business, all the mattresses are built to order in a suburban factory.

TIM: We’re not a marketing company that has someone else build the beds and ship them out. We have total control over what the customer’s getting and it’s successful for us. We build 400 to 500 beds a month. But that’s a lot for a little company. There’s only six or seven of us that work here full time and it keeps us busy all the time. We do our own maintenance on our equipment, we’re the builders on the beds, we do the packaging, we do local deliveries, so yeah, we’re pretty proud of where we’re at today. We’ve always had like steady, slow growth. We don’t want to have big influxes of business ’cause I worry about production, like I still like to be so hands on with what’s being built, how are things going through.

WAILIN: Tim’s showroom has just a dozen or so models for sale, and they’re named for people: The Scot, after the store’s first employee, or the Leona, after the wife of the man who started the business. Some of these models have been around for decades and they haven’t changed very much.

TIM: We don’t carry products that are real trendy, that we don’t have a lot of experience with, that we don’t know how they’re going to react with customers. But what we do carry and what we produce are mattresses that are really time-tested and well-received.

WAILIN: Tim’s been at this for so long that he’s developed a kind of sixth sense for whether a customer is a side sleeper or stomach sleeper, just by looking at the person.

TIM: A lot of times, we get customers that come in: “I want a firm mattress.” And you look at their body type and you determine, okay, are you a side sleeper? And then I’ll tell them, “I don’t want to build you a firm mattress. I’ll build you something real supportive, but not too hard. Your legs will go numb, your arms will go numb.” I learned that years ago, we would make mattresses and a lot of these older guys come in: “I need a firm bed.” And next thing you know, they’re calling you two weeks after they get the bed, “Can you make it a little softer?” A lot of people, when they ask for a certain product, it’s like, “I’ll show you that, but this is what’s going to be a better fit for you and this is the reason why.” Sometimes, though, I’m not the guy for the customer, like I’ll try, I can always make our beds feel a little firmer, a little softer if the customer wants something a little bit different than what we offer. But there have been times where I tell them, “I’m not the one for ya.” Like it’s—for your needs, and for the softness level that you want, I can’t make that bed because I don’t feel like I can stand behind it the way you want us to make it. Twenty years ago, I kept running myself through the wringer, well I’ll make it firmer, I’ll make it softer, what do you wanna do? I kept changing things and I’m like, it’s not getting any better and I’m getting pretty worn out from this whole thing.

WAILIN: Tim’s store, Quality Sleep Shop, was started in 1969 by a former foam salesman named Robert Brixie, who traded his house for the store’s first building. He and his family lived in an apartment above the shop. Now he lives nearby and still pops in once in a while.

TIM: Mr. Brixie, the original owner, what a great guy. I started with him in 1990 after school. I loved him. He was such a perfectionist. He’s an old Navy guy and just a big man, and he had this big booming voice and he’d always say, “You can’t cheat ‘em! Believe me, these old people would bang down the front door saying give me my money back if you make a mattress that doesn’t hold up!”

WAILIN: Tim had just graduated from high school when he went to work at Quality Sleep Shop.

TIM: One of my sisters actually dated a guy that used to work for Mr. Brixie and I needed a part-time job and he goes, “Go see Mr. Brixie, he’s a good guy to work for.” So I started there and I knew it down to my shoes that this was what I was gonna do, yeah, loved building these beds. The mentoring from Mr. Brixie was great, but I really enjoyed the physical building of the product too. Mr. and Mrs. Brixie lived upstairs and i’d be working in the shop downstairs. We had a showroom in the front of the store, and every day, Leona or Lee, would come down with like pie or hot tea. She’d always make something for ya in the middle of the day. What a nice thing! You’d get to sit down and eat something homemade. Yeah, they really treated you so nice. It was just before the mattress shop on every corner type of environment and we were competing with the Sealys, Stearns and Fosters, and there were some independents. Like there were more independents, but they kept going bankrupt. And I asked Mr. Brixie, the original owner, I’m like, “Mr. Brixie, are you nervous about going out of business?” And he said, “No!” And I’m like, “How can you be so confident?” He goes, “I never cheated. These other mattress companies, if they get short on money, they would start putting in subpar filling materials. I never cheated. If we were low on a certain SKU, whatever that product was, we’d always upgrade it. We never would go down. You always do one better, even if it hurts you a little bit there, it helps you in the long run.” But that’s why he was so confident not to go out of business. So it took out all the guys who weren’t as healthy, but the ones that do a good job stayed.

Mattresses years ago used to have buttons in them. It was called button tufting. We did them inner tufted; we would put rows of buttons on the interior of the bed. A customer, a lady says to me, “How do I know you’re gonna put those buttons in there?” It never crossed my mind not to put a button in, like I couldn’t complete a bed, like if our button tufter would give us trouble, if it was missing one button, it would not get sewn together. When I first started working there, he says, “Never lie to a customer. You never tell anybody anything just because they want to hear it. It’s gotta be the truth.” So when the lady asked about those buttons, I was like, “I don’t know how you would know if the buttons are there are not, but they’re there.”

WAILIN: In 1994, Tim was 24 years old and considering a change.

TIM: And I say to Mr. Brixie, “Mr. Brixie, I gotta get a real job.” And he said, “If you quit, I’m gonna go out of business.” and he goes, “My kids don’t want it; I’m ready to retire. Give me one more year, your same pay rate,” which I was making nine bucks an hour and so I’m like okay. So one more year comes, I’m 25 years old and in September 1st of 1995, I bought the company from Mr. Brixie and I was so scared. I borrowed a third of the money from him, a third of the money from my parents and a third from the bank. And the bank loaned me the money at nine percent interest and Mr. Brixie goes, “I’ll loan you a third at eight percent,” and my mom and dad go, “We’ll do eight percent too.” I remember at the closing at the bank, it was around lunchtime, a little bit after lunch and I go to my dad and my mom, “Wanna get some lunch?” My dad goes, “No, you’ve got a lot of mattresses to make,” so it’s right back to the shop I went. And I never took a day off. All I did was work. I was so scared to fail or not pay anyone back.

WAILIN: Tim moved into the apartment above the shop, where Mr. Brixie had lived, and kept making mattresses the way he’d been taught. But he did make a few changes. He expanded the shop’s delivery radius into the city of Chicago. He made a lot of deliveries himself, and sometimes his girlfriend, Cindy, would tag along. Another big development came along in 2006. By then Tim and Cindy had gotten married and had a daughter, Emily.

TIM: My daughter Emily was born with severe eczema and all kinds of allergy issues, like, I felt so bad for Em when she was born, like her stomach was so distended and her skin was so dry and cracking all the time. And my wife said, “Why don’t you make her an organic crib mattress?” So I was like, “Yeah no problem,” like I would make organic mattresses every now and again, like onesie twosies. Never thought much about them, but it seemed to make sense for our family. After I made that, I’m like, “Cindy, we’re not the only family with these health issues and we should offer these to our consumers.” We would spend like an hour, hour and a half every night, well more like two or three nights a week, for a year, working on a product line one, and then how do you describe it to the people and how do you put a website together. The rabbit hole gets really deep: Okay, where’s the wool sourced from? What’s the wool washed with? Is it treated with anything? t gets pretty complicated and it was a learning curve for sure on our end. Now, all our distributors, everyone that we work with on our end, I physically visit the plants and make sure that what they say is what they’re doing and I follow each product through.

WAILIN: Tim sold his new line of organic mattresses in his showroom while he and Cindy worked on the website. In 2007, they launched a new brand called My Green Mattress and started shipping nationwide. Like other mattress-in-a-box companies, Tim’s organic mattresses come rolled up and unfurl when they’re unpacked. The crib mattress is called the Emily, after Tim’s daughter, whose eczema eventually cleared up.

TIM: Our philosophy is let’s build a bed that’s really nice, very durable and that’s so approachable on price, like we’re right there with the major brands with their traditional built beds for the organic, so it’s a really good model. How we stay affordable is every morning I’m at the shop, I’m working on equipment, everybody’s doing their part here, we’re all working really hard on building these beds, but then it all goes direct to the consumer. There’s no middleman.

WAILIN: This business model has helped insulate Quality Sleep Shop from the competitive threat of corner mattress stores. Where Tim has ceded some business is in twin and full beds. He thinks a lot more people are shopping at Sam’s Club or Costco for those smaller mattresses. But Tim still sells a lot of queen- and king-sized beds, and he recently hired a director of marketing to lead a bigger push for My Green Mattress. In selling online, Tim has the potential to reach a much broader audience for his organic beds, but it also puts him in competition with the many mattress-in-a-box startups that have raised venture capital and gotten a lot of press.

TIM: I think those companies are great. They simplified it. It’s a memory foam bed, they all seem to be at the $800 price point, not much variation in those mattresses, but I think it fits a need for the millennials, for the people who don’t want to shop. With My Green Mattress, we’ve shipped mattresses since 2007. What do I know about anything really? I’m just a mattress maker, but it always amazes me that someone would buy a mattress online — I wouldn’t be able to do it, but so many people do.

WAILIN: Tim might describe himself as just a mattress maker, but his principles as a business owner have served him well. Keep it simple, never cheat. It’s a quiet but powerful contrast to Big Mattress, which pumps out hundreds of virtually indistinguishable models, all marked up a hefty amount. It’s a good business for the large mattress companies and their private equity investors, but Tim wants no part of it.

TIM: For whatever reason, we’re doing well. Like even the small independent bookstores, like I feel bad for a lot of those bookstores that have gone under. There’s so much knowledge you get from, you know what I mean? Those little places. I’m starting to think of my company as like a microbrewery. You can get some really good beers from someone, you may never have heard of it, but you can’t wait to have another one of those beers, and it’s kind of like our mattresses. You may not have heard of us, but once you try it, you’re like, “That thing is awesome.”

WAILIN: The Distance is produced by Shaun Hildner. Say hello.

SHAUN: Hello.

WAILIN: And me, Wailin Wong. Hello. And also good-bye, because this is actually the second-to-last episode of The Distance.

SHAUN: Now this is a super awkward good-bye, like when you say good-bye to someone on the street, but you keep walking the same way.

WAILIN: That’s exactly what this is like.

SHAUN: You’re going to hear us again in two weeks.

WAILIN: You are going to hear us again in two weeks. And we’re working on a new show, so don’t go anywhere. We’re working on a new show, and we’ll bring you more updates in a couple of weeks. Is there anything else we should say?

SHAUN: Yeah, our illustrations are by Nate Otto. And we are a production of Basecamp.

WAILIN: Basecamp is the app for helping small business owners stay in control of projects and reduce email clutter. Try Basecamp free for 30 days at basecamp.com/thedistance.