In 1972, when two cousins opened Northwestern Cutlery, their knife rental and sharpening business, they chose a location in Chicago near the city’s meatpackers. Over the next decades, the dramatic transformation of the neighborhood around the business meant a nearly complete turnover in Northwestern Cutlery’s customer base — from industrial meatpackers to affluent gourmands.

Today, Marty Petlicki, the son-in-law of one of the original owners, runs Northwestern Cutlery. He’s honed his skills at the grindstone over many years while also paying keen attention to how his customers’ needs have changed during that time. The result is a store that calls itself “the candy store for cooks,” and it’s one of the few places you can get your knives hand-sharpened and buy professional grade bakeware or a three-foot-tall pepper mill. (I saw it on the shelf and Marty says it really works, so that’s a tip for anyone who’s opening a restaurant for giants.)

Transcript

WAILIN: Marty Petlicki learned how to sharpen knives 30 years ago while working at his father-in-law’s store, which rented knives to meat packers, butchers and delis around Chicago.

MARTY PETLICKI: There wasn’t a lot of training involved because it’s hard to tell somebody how to do that, because you have to get the feel for the knife on the grindstone. You just have to get used to it, and I kind of figured it out myself, but it took a long time. I didn’t always get to do the best customers with it, you know, I got to do the customers where they didn’t care that much. It was frustrating. There was a lot of holes in the wall where you’d get frustrated and you’d throw the knife and (laughs) yell real loud. There were never any customers in the store, so you didn’t have to worry about that, it was just a shop.

WAILIN: Things are much different these days at Northwestern Cutlery, the business that Marty Petlicki’s father-in-law started with a cousin in 1972. Marty’s now the owner. And the shop has gone from a small knife rental business to a full-fledged retail store that sells cookware and supplies to restaurant workers and home cooks.

MARTY: There’s still companies out there that that’s all they do, is they rent knives. We are getting away from that because the neighborhood is changing so much. As a business, you have to kind of go with the flow and let your customers dictate where the business goes.

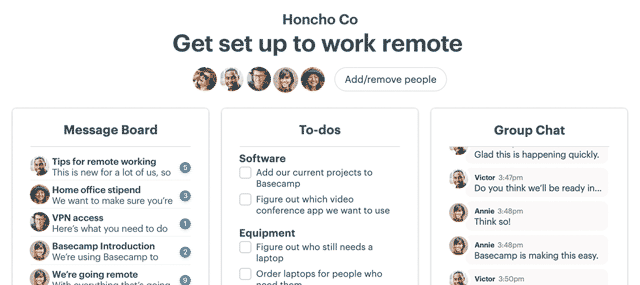

WAILIN: Welcome to The Distance, a podcast about long-running businesses. I’m Wailin Wong. On today’s show, how Northwestern Cutlery went with the flow of a dramatically changing neighborhood, and ended up with a completely different kind of customer in the process. The Distance is a production of Basecamp. The brand new Basecamp 3 helps small businesses stay in control of projects and reduce email clutter. Tasks, spur of the moment conversations with coworkers, status updates, reports, documents and files all share one home. And now your first basecamp is completely free forever. Sign up at basecamp.com/thedistance.

MARTY: It’s an old school shop, it’s not decorated very nice. It’s dusty. You know, the knife sharpening creates a lot of dust, so everything gets like that.

WAILIN: Marty’s father-in-law, Henry Colonna, opened the business with his cousin in 1972. He came from a part of northern Italy where knife sharpening was a specialty, and he practiced the trade in the U.S. before and after serving in the Korean War.

MARTY: Before he went into the army, he was working for somebody and they had a truck and the grindstone was inside the truck, attached to the drive line of the truck, so you’d turn the truck on and the grindstone would go and they would drive around and they would pull up to a butcher shop or a packing house in the stockyards. Everybody would run out.

WAILIN: After Henry got out of the Army, he ran his own shop out of his house on the northwest side of Chicago.

MARTY: He had a big grindstone in his basement. Everybody knows the story of the guy wheeling the grindstone down the alley, and that’s kind of what it was, was a big grindstone. It was just set up on a bench with a motor attached to it instead of pedaling it.

WAILIN: Henry’s cousin had his own knife sharpening business and in 1972, the two men combined their operations. Three years later, they moved the shop to a small brick building under the elevated train track in Chicago’s Fulton Market neighborhood, where Northwestern Cutlery remains to this day. By the time they moved in, the area had already been an industrial food hub for over a century, and Henry and his cousin wanted to be near the meatpackers that populated the neighborhood. For many years, no one visited the store. There was no reason to, because Northwestern Cutlery made deliveries. Marty’s first job when he started working there in 1986 was driving the route.

MARTY: There was no phone, there was no GPS, there was a map and they would give me a stack of cards with the address on it and how much we charged the customer. I had all the knives rolled up in paper in the back of the—it was a station wagon, and all I had were these cards and I had to find the customer, go here you go, okay! (Laughs) So yeah, it took me a lot longer than normally, but I got it done and I would leave real early and come back at the very end of the day and they’d go, “Where were ya?” I’d go, “Where did you think I was?” I don’t know where I was, was what I told them, but I got everything done.

WAILIN: Eventually, Marty came inside and started sharpening knives. As he gained more responsibility at the shop, the area around it started to change. Here’s Michael Roberts, a longtime Northwestern Cutlery customer and fellow business owner in the neighborhood. He owns Prairie Production, a photo studio and event space, and he remembers what the area looked like when he moved there in 1982.

MICHAEL ROBERTS: The sidewalks were cracked up. There were hookers on Lake Street and meatpackers all night long up and down Randolph and Fulton.

WAILIN: For Michael, the neighborhood started changing in 1996, when then-Mayor Richard Daley cleaned up the area to get it ready for the Democratic National Convention. It was also around the late 90s and early 2000s that Marty started getting actual customers at his store.

MARTY: A few restaurants would start moving in onto Randolph Street and they would come in. They had their knives sharpened because they knew we were there, and they would ask for something, whether it would be a certain kind of tool to use in the kitchen and we’re like, “Okay yeah, we’ll get one for ya,” you know, because you never turn anything down, and a lot of times you’d say, “Yeah, we’d get one for ya,” and it’s like, “What is he talking about?” (Laughs) But you’d call somebody and you’d find out and you’d get one. You’d get one for him and we would get one for the store, and we’d put it in the store and if somebody else wanted it? Okay, then we would get more and it’s kind of how the store progressed, just by people asking for things.

WAILIN: Over at Michael Roberts’ photography studio, he was doing shoots for food clients who would sometimes need a certain kitchen gadget or tool at the last minute. He would send them to Northwestern Cutlery. And culinary schools came calling, needing knife kits for their students.

MARSHALL SHAFKOWITZ: We give them a ten-inch French knife, a twelve-inch slicer, a eight-inch bread knife, a paring knife, boning knife…

WAILIN: That’s Marshall Shafkowitz, the dean and executive director of the Washburne Culinary and Hospitality Institute in Chicago. It’s the city’s oldest culinary school. Washburne students get their knife kit on the very first day of school. The set also includes a curved blade called a tourne knife, as well as some spatulas and spoons. Washburne was one of Northwestern Cutlery’s first cooking school customers, and while it’s since switched suppliers for the knife kits, Marty still gets business from culinary students looking to branch out beyond their school-issued tools.

MARSHALL: As students and as chefs, knives become incredibly personal, so it’s great that students learn on these generic knives that they can carry with them anywhere they go in the world, but as you gain confidence and gain skill, you begin to figure out what feels better in your hand. We give them the basics and then they start to build their additional pieces to their kit as they can afford them.

WAILIN: Culinary students eventually become professional chefs, which is the kind of customer Marty wants because they buy more expensive knives. So do many home cooks, especially ones that watch television and follow celebrity chefs.

MARTY: The biggest thing that has helped are the cooking shows because they have these chefs on there and they see the things that they use, and boy when they see it, they want it, you know, so if you’re watching a show and you see a new item that a chef is using, yeah you want to get it because people are gonna call and ask for it.

WAILIN: The shift in clientele meant Marty had to rethink his inventory, especially his knives. The economics of renting knives demanded relatively cheap ones that got the job done but were inexpensive enough for the store to make its money back on rentals. As Marty’s rental customers were supplanted by individual restaurant workers and home cooks, he needed to stock more high-end merchandise and rethink his sharpening services. A grindstone, which is used to thin out a knife or fix a broken tip, doesn’t have the precision and finesse needed for a high quality blade. For those jobs, you need a belt machine and bench stones of varying coarseness.

MARTY: Here, we’re using our belt machine and all this is for is putting new edges on the knives and we try to duplicate the manufacturer’s edge when we do this, so you’re taking off very little steel of the knife. You’re not trying to wear out the knife.

WAILIN: Knife sharpening is about feel and sound. There are subtle variations in how a knife sounds as it gets thinned out on the spinning disc of a grindstone or polished on a bench stone. Here’s Marty on the grindstone.

MARTY: Listening for consistency, the sound. Once you get a nice even sound, you know that you’ve put a proper bevel on the knife and thinned it out the way it should be.

WAILIN: It’s louder at the beginning because…?

MARTY: It’s louder at the beginning because the edge is uneven. You’re going through highs and lows on the steel of the knife so the pitch changes as you go over that, but as everything smooths out, you can tell that the sound always smooths out also.

WAILIN: On the bench stone, a small abrasive block used for the finest level of sharpening, Marty uses swift but sure hand movements to swipe the blade at an angle, producing just a whisper of a sound.

MARTY: You’re listening to it too, and you’ll notice that every step of the way, it gets a little quieter each time because you’re using a finer stone, less abrasive, so there’s less noise. We’ll start off with a coarse stone to establish the edge on it and put a new edge on there, and from there it’s a polishing process so the coarse stone is going to leave deep scratches in there, so then you want to polish those out, and the more stones you take to do that, the better the polish it’s going to be, the stronger and sharper the knife is going to be. But if you’re buying a knife that’s worth, you know 3, $400, maybe more, you really need to do it that way in order to do it justice to the knife and get the most out of it.

WAILIN: Northwestern Cutlery’s ability to do hand sharpening is what helps distinguish the business from what Marty calls the grinders, or the knife rental shops. He still rents knives to a small group of long-time customers, but he hasn’t taken new rental clients for six or seven years now. Many of his old meatpacking clients in the neighborhood have closed or relocated. His focus is on the premium sharpening and on refining his inventory, which includes not just a huge array of knives, but chef’s uniforms, bakeware, and modernist cooking tools like sodium hydroxide and sous vide equipment. The business calls itself the candy store for cooks.

MARTY: Tweezers. I never in my life thought that we would have 20 different types of tweezers on display but we do and we sell ’em all.

WAILIN: Marty tries to maintain the feel of a neighborhood store, something that resonates with locals like Michael Roberts, the photography studio owner.

MICHAEL: When I was a young child, my grandmother had a corner grocery store so you know, from the time I was a tiny child, that was what I found familiar and comfortable. So why would I go out of the neighborhood if I could get what I want here?

WAILIN: Marty’s owned the store since 2011, when his father-in-law, Henry Colonna, passed away. Northwestern Cutlery is serving a very different kind of customer now than when Henry ran the business, but Marty says he’s still putting into practice what he learned from his father-in-law about customer relationships.

MARTY: We’re in the service business, so you complete your service no matter what. So even today, somebody wants something special ordered, you do everything you can to help the customer and that’s from the beginning of the company. It’s always been that way, so it’s really locked into our company, whereas some companies don’t always do that. You know, they’re not service-orientated companies. They’re sales-orientated companies.

WAILIN: If you walk through Fulton Market today, the ongoing neighborhood transformation seems dramatic and relentless. The area is filling up with luxury condos, office buildings and restaurants. But for Marty, the way he’s adapted Northwestern Cutlery in the last couple decades has been a quieter, more gradual process. And that suits him just fine.

MARTY: We don’t need to grow, we don’t need to double business in six months. We hope to do better this year than we did last year, and we usually do that and it just kind of plods along but people, they hear about us and they come in. We don’t want to get too busy or too slow. That’s the way we’ve always worked it, really, we don’t look to move to a bigger building or anything like that. I’ve seen businesses do that and they end up just collapsing under their own weight. So we own the building, we own the parking lot next door and it works. We’ve got a good group of employees. Everybody’s been here for a long time. I try to take care of ’em the best I can and they take care of me, they’re all very good, I think, they’re happy working here, and that’s enough, you know, that makes for a happy existence.

WAILIN: The Distance is produced by Shaun Hildner and me, Wailin Wong. Our illustrations are done by Nate Otto. Thanks to Russ Maki for the introduction to Northwestern Cutlery. We featured Russ’ business, Graphic Conservation Company, on The Distance back in February. You can find that story, along with all other episodes, at thedistance.com, where you can also sign up for our newsletter. The Distance is a production of Basecamp, the app for helping small business owners stay in control of projects and reduce email clutter. Your first Basecamp is completely free forever. Try the brand new Basecamp Three for yourself at basecamp.com/thedistance.