In 2010, as Worksman Cycles was emerging from the recession and ready to grow again, the maker of heavy-duty cycles saw an exciting opportunity to supply the bikes for New York City’s bike share program. But the city rejected Worksman’s proposal, and that disappointment lay the groundwork for the company to relocate to South Carolina, leaving behind the city it had been in since its founding in 1898.

This is the second part of our story on Worksman Cycles. If you missed the first episode, which explores the company’s history and commitment to keep manufacturing bikes in the U.S., be sure to catch up!

Transcript

WAILIN WONG: Hi everyone, it’s Wailin. This is the second episode in our two-parter about Worksman Cycles, so you should go back and listen to the previous episode if you haven’t already. It’s about how Worksman found its niche making industrial cycles and kept its manufacturing in the U.S. even as the rest of the American cycle industry moved overseas. And now here’s the second part.

Worksman Cycles was founded in 1898 in New York. Its first factory stood where the original World Trade Center would later be built. The company’s industrial tricycles and bicycles are used in factories worldwide, but they’re also a constant presence on New York city streets as delivery vehicles. The vending division at Worksman invented the stainless steel hot dog cart. It doesn’t get much more New York than that. Wayne Sosin, the company’s president, grew up in Queens. But in 2015, Worksman decided to migrate south.

WAYNE SOSIN: So how does a company that’s been in New York City for 118 years end up in Conway, South Carolina? Now that’s a good question.

WAILIN: Welcome to The Distance, a podcast about long-running businesses. I’m Wailin Wong. On today’s show, how Worksman Cycles’ desire to stay and grow in America meant leaving the only city it’s ever known.

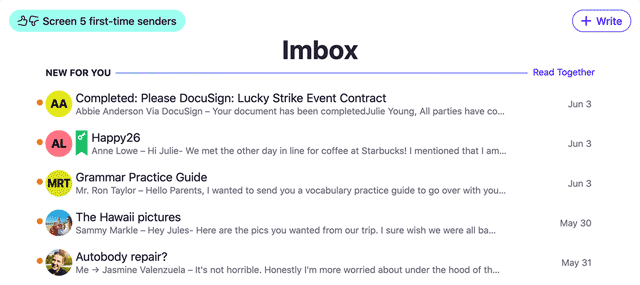

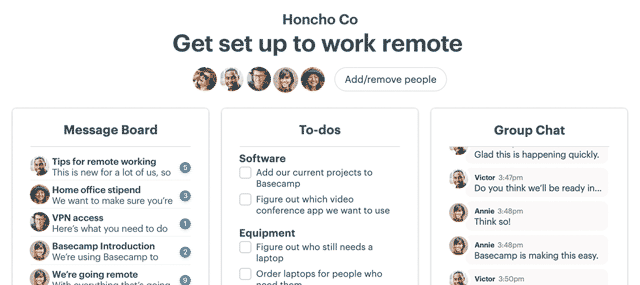

JANICE: The Distance is a production of Basecamp. I’m Janice, a customer support rep at Basecamp. Basecamp is the better way to run your business. It’s an app for communicating with people and organizing projects and work. If you’re feeling overwhelmed by email, chat and meetings, give Basecamp a try. Sign up for a 30-day free trial at basecamp.com/thedistance.

WAILIN: We’re in the company’s factory in Ozone Park, Queens, It’s a century-old building that once made hats, and later birthday candles. Worksman has been there since 1979. At the time I visited, in late March, they were still making some wheels at this factory while they gradually shifted those operations to South Carolina. Here’s Bruce Weinreb, who handles sales and marketing at Worksman.

BRUCE WEINREB: We’re making bikes in such a traditional way that if you walked into this building in 1979, or if it was a bicycle factory, 1940, it would have been very much exactly how we’re doing it today. So you can see we’re lacing wheels by hand.

Truing is when you make a wheel so it doesn’t wobble side to side. Every one of our wheels gets trued by hand. We’re talking many, many thousands of wheels every year.

WAILIN: At the new factory in Conway, South Carolina, the work of making wheels and balancing them is done largely on modern equipment.

WAYNE: The first machine places the spoke into the rim so that the nipple of the spoke gets tightened onto the rim to a certain tolerance, such a good tolerance that it can go through this robot over here and this robot will do the balancing of the wheel robotically, so if you watch, you see the wheel is being measured right now for its true-ness.

Once we have the automated system working, it’s probably about 40 percent more efficient, which is a huge amount, I don’t have to tell you that, but we make so many unusual wheels and we do a lot of small runs that sometimes re-setting up a machine to run 20 wheels, it doesn’t pay. The setup time is so lengthy that by the time you set it up, you could have done it by hand. So we’re doing a combination of old and new.

WAILIN: It’s not like Wayne just decided one day to go shopping for a more modern manufacturing facility and decided on Conway. The story of why Worksman left New York actually starts in Dallas, Texas, in 2010. Wayne was in town for the red carpet launch of that year’s Neiman Marcus Christmas Book, the department store’s annual catalog of over-the-top, outrageously expensive holiday gifts. Worksman had a $4,500 adult tricycle in the catalog that year, featuring fabric by fashion designer Tory Burch. While Wayne was in Dallas, he called aerospace company Lockheed Martin, one of his customers, and asked if he could visit their facility.

WAYNE: They put me on the back of a golf cart—not a tricycle, but the back of a golf cart—and they gave me an official tour that took an hour and a half and they were showing me amazing things, the most modern factory I’d ever been in in my life. And the day I was there, the Kuwaiti airforce was being trained and flying F16s and I was outside watching them do touch and gos. It was amazing. So you go through this incredibly ultra-modern robotic plant and we saw our tricycles all over the place and when I’m done, a naval official is waiting for me. He says, “Are you Mr. Sosin? How’d you like the tour?” I said, “Well, to be honest with you, I wasn’t expecting this kind of VIP treatment. I can’t thank you enough.” He goes, “Well, do you want to know why we gave you that VIP tour, as you call it? We couldn’t run this plant as well as we do without Worksman tricycles.” And that reinvigorated me so because over the years, we’ve always been told oh you know, your technology, it’s so old-fashioned, who’s going to use this? There’s all sorts of modern things. Segway came out, oh they’re gonna cook your clock and you’re not gonna have tricycles anymore. And then I have the most modern facility at the time in the country tell me they can’t run the plant without Worksman tricycles? It just got me so motivated, and that’s one of the reasons that we knew we had to take the next step to grow the company.

WAILIN: By then, 2010, Worksman was coming out of the recession and seeing business pick up again. Wayne felt like the company was bumping up against its production capacity and other constraints in New York.

WAYNE: Taxes are high, getting trucks in and out of our facility was never easy, and we said, “Well, maybe we should be looking at something else one day.” But that’s a very big decision to make. Well, at the same time or shortly thereafter, New York City announced that they were looking for a company to run their bike share program. And we said, “Bingo, this is it.”

WAILIN: Worksman had already supplied the cycles for bike sharing programs in cities like Tulsa, Oklahoma, as well as on college campuses. Bike share was a good fit for Worksman because it makes industrial strength cycles. One of their bicycles can hold up to 500 pounds. Wayne sells bikes to overweight riders who need something stronger than what other companies make, and upgraded tires on Worksman tricycles can roll over metal debris on factory floors without popping.

WAYNE: We make heavy duty bikes and that’s what bike share is all about. New York City at the time said they were looking to deploy 50,000 bicycles within 6 years, which would just be an incredible growth opportunity for our company and we really wanted it in the worst way. We went ahead and put the proposal together and immediately, within three weeks, got a letter of rejection, which we did not deserve. But it was a huge, huge turnoff to us. The city we’d been in for 114 years at the time really shunned us. We weren’t shy about telling the press it didn’t happen and that we were treated pretty disrespectfully, in our opinion and I came out with a quote, something to the effect of, “Well, I guess New York City doesn’t appreciate our 60 manufacturing jobs. Maybe one day they’ll lose them.” It was sort of just an idle rant, if you will, but it was from the heart. I was, we were really hurt by this. So anyway, we started getting contacted by some states saying, “Gee, we heard you’re not so happy in New York. We’d love to have Worksman Cycles in Virginia, in Tennessee, in Kentucky.” If you can bring jobs to a state, they would do a lot of things to help you to make that happen. Well, we became very open-minded at this point. We looked within New York City. There was— Real estate was unavailable or unaffordable, I should say. And then you start looking at real estate that’s one-tenth the price in these states. In fact, the state of Kentucky literally offered us a building for a dollar. If we employed x amount of people, we could lease the building for a dollar a year and buy it for a dollar at the end. Myrtle Beach Regional Economic Development called one day and said, “Gee, we’d love to meet with you guys. We think it’s a great place to manufacture product.” And I’d been to Myrtle Beach so many times on golf trips and vacations and just didn’t see that as being a place that had a manufacturing base, but I was certainly open-minded.

WAILIN: Conway, South Carolina is about 15 miles northwest of Myrtle Beach, in the same county. And if Wayne thought he had gotten the VIP treatment at the Lockheed Martin plant in Dallas back in 2010, he really got courted in Myrtle Beach. There was a technical college in the area and local officials said they would help train welders and machinists for Worksman. They offered tax incentives. And real estate costs were a fraction of what they were in New York. Wayne found a building in Conway that used to be a tobacco drying warehouse and a printing facility for a t-shirt company. It had a concrete floor and high ceilings and the right amount of square footage.

WAYNE: And all the city officials for this little company, Worksman Cycles, came to visit me and wanted to meet with me and invited me to see their operations. And it was the warmest feeling that you ever got of people who really wanted you to come even though, to be honest, we’re a small company. We only promised 40-some odd jobs and they made me feel like we were General Motors trying to come down here. That’s how they treated us. When we were able to locate this building, everything else fell into place. Hey, if it means moving out of New York to lower some of your real estate costs and get some tax incentives, you do what you need to do to keep the company going on the right path.

WAILIN: The Worksman factory in New York is just under 100,000 square feet, but that’s split into three stories with the kind of odd corners and columns that come with a 100-year-old building. In Conway, the building is just one story.

WAYNE: Our analysis is you get about 20 percent more space out of the one story building and you save a lot of time in material movement. We spent an awful lot of time moving things in elevators and it’s very wasteful, especially when you’re dealing with steel, which is very heavy, so always the logistics of doing the manufacturing in a three-story building was challenging, to say the least. For all the years I’ve been in the business, we’ve had a three-story building and we’re telling companies around the world, “You should use our tricycles to get around. It’s more efficient than walking.” Well, in a three-story building, it’s not really practical to ride a tricycle, as you can imagine. But here, we use them constantly. We have five tricycles assigned to different people who have mobile tasks. There are Worksman tricycles for the first time in our own factory. We used to tell companies, “If your building’s about 200,000 square feet, you really need a tricycle. If it’s a million square feet, you need lots of tricycles.” But we never realized that in a 100,000-square foot building, you could really use a tricycle in a much smaller space than we ever really had marketed as such because like I said, the five tricycles we have here, we use constantly. When we tell companies now that they should use trikes, we can say it firsthand.

WAILIN: In Conway, Worksman had the ability to design a factory that would address the shortcomings of the New York space and give the company room to grow. In New York, Worksman made its cycles to order because it had neither excess production capacity nor space to put them. In Conway, the company can actually build up an inventory of finished cycles. And the manufacturing processes got an update, with robotic welding equipment and a new powder coat system for painting the cycles. Many of the workers are also new.

WAYNE: We’re up and running for less than a year, well under a year, as far as what you’re seeing now. We’re probably at this capacity only for about 3 months, the capacity you’re seeing now, and virtually everybody here is new. We’ve had to train an entire staff who had never worked in a bicycle factory before because let’s face it, there are no bicycle factories in the U.S., so we had to train everybody from wheel builders to powder coaters. But it’s been great because in a way, everybody who came here started out “Let’s see what you can do.” And now the person running our powder coat system was the person we first hired to unload trucks and he’s doing a marvelous job at that. The young man who’s running our wheel-building equipment, we got him at a vocational school, didn’t know that he’d have this skill level. We just thought he’d be somebody putting tires onto bicycles, and he’s doing a wonderful job of working our most complicated machine. It’s a really eclectic, interesting mix of people, men and women from all over the country. And not everybody’s southern but the ones that are have taught me that the plural of “y’all” is “all y’all,” and they’ve taught me that “a piece down the road” is a lot further than you might think. They’ve taught me where yonder is, it’s somewhere over there. So we have the Southern influence, but it’s actually interesting because I would not say that it’s a very Southern oriented overall staff, it’s probably 50–50.

WAILIN: Worksman gave all of its employees in New York the opportunity to relocate to South Carolina. Several workers did move to Myrtle Beach, although fewer than Wayne hoped. Other Worksman employees found jobs elsewhere or will be leaving as New York cycle manufacturing operations wind down over the next year. Still others were reassigned to Worksman’s vending division, the part of the business that makes stainless steel hot dog carts and outfits food trucks with professional kitchens. That division will stay in the old building in Queens. But most of the facility will be emptied out, and Wayne didn’t just want to leave an abandoned shell.

WAYNE: We had an opportunity to sell off the building and most of the interest we got was from self storage buildings, and they offered a lot of money to buy the building and when I realized that in a building our size, they would employ approximately five people, it was a huge turnoff to me and I didn’t want to be a hypocrite. We didn’t want to be hypocrites.

WAILIN: Wayne found a company that divides old factory buildings into small spaces and rents them to makers of physical stuff.

WAYNE: You have to produce something or you cannot rent from them. I went to visit one of their facilities. It was so cool. You see everything from furniture makers to artists to small welding operations, but every one of these small, let’s say thousand, 2,000-square foot facilities was making something. And I said okay, that’s pretty cool, so actually in our building, there’s going to be more people employed there than we ever employed there and all the people employed there are making something.

WAILIN: Worksman Cycles depends on people making things. A small welding operation in 2,000 square feet isn’t a customer for a Worksman tricycle, but maybe one day it’ll be a big welding operation in a 200,000-square foot factory.

WAYNE: My son went to Lehigh University in Bethlehem, Pennsylvania. Now the last time I’d been in Bethlehem was probably 15 years earlier, when it was the most vibrant steel plant in the country. It was a city within a city and they must have had 200 Worksman Cycles deployed in the facility in Bethlehem and I remember going there, it was just such a cool place to see, molten steel and it was cool. Well, I went back with my son 15 years later to look at the school and I passed this rusted out nothing. Even telling you now, I get tearful because it was so sobering to see that. You could drive for miles by the old Bethlehem steel plant and it was nothing, it was zero. It was rusted-out structures, not a person there, it was horrible, tumbleweed practically growing if they had tumbleweed in Pennsylvania, that’s what it would look like. It was heartbreaking to me. Well, that’s a customer we’re never getting back. Never. You know, it was replaced by a casino and a hotel. It’s not the same. There were 40,000 people at one point who worked in Bethlehem at Bethlehem Steel and all the supporting companies that supported them, all the suppliers, the ripple effect that we’re talking about. We were just a tiny little cog in that, but you know what? That was a good customer for us. We’ll never get it back. If there’s no manufacturing, yeah, we’ll find other places to sell our tricycles or bicycles for bike share. We’ll reach out to consumers, which we hope to become a much bigger part of our business. But the backbone of our business is American manufacturing. And if they’re not manufacturing, we’re not selling bikes.

WAILIN: Worksman’s role as both a manufacturer and a supplier to manufacturers gives it a unique vantage point on the state of American industry. Like other factories, Worksman will be relying more on automation in years to come. That means fewer humans in the plant, and Worksman needs people riding its cycles. These dynamics are constantly in play, and Wayne watches them carefully.

WAYNE: We have to see American factories successful and if that takes more robotics, well, so be it. Robots can’t ride tricycles, but at least there are other people that are working in the plant. So yeah, I don’t think a lot of jobs are ever coming back. I’m realistic enough to know that, but I’d rather take half a pie than none of the pie.

WAILIN: The story of Worksman is about staying and leaving. It’s worked hard to stay in the U.S., even when doing so didn’t seem to make economic sense, but it had to move away from its hometown to make a long-term bet in a new American city. It turns out it is possible to leave New York, even if you’re a century-old company or a guy from Queens who never imagined himself living in the south.

WAYNE: It’s just a whole different feeling that there’s a support system behind you. It’s really more than the incentives—the real estate costs and the cost of living being so reasonable and a nice facility to have and a pleasant place to live, so it all sort of fell into place. So it was never really the written plan to end up in Conway, South Carolina, but I have to tell you, through that whole series of events, I couldn’t be happier with where we ended up. In the last two years, I’ve traveled back and forth to New York 42 times. I wake up in the morning very often, have to open my eyes and remember, am I in South Carolina or New York? But other than that, it’s pretty cool.

WAILIN: The Distance is produced by Shaun Hildner and me, Wailin Wong. Our illustrations are by Nate Otto. You can find us all over the Internet. We are on Twitter—actually, we’re not all over the Internet. That’s not true. Because we’re, like, only on Twitter, and we have a website. You can find us on Twitter at @distancemag, that’s @distancemag, and you can also subscribe to our podcast via Apple Podcasts, Google Play Music, or wherever you get your podcasts. What else am I missing?

SHAUN: We’re a production of Basecamp.

WAILIN: Oh yeah, we are a production of Basecamp. The Distance is a production of Basecamp, the app for helping small business owners stay in control of projects and reduce email clutter. Try Basecamp free for 30 days at basecamp.com/thedistance.