I’ve been working on some video tests with the iPhone and I needed to mount it on tripod for some steadier shots. Some folks in the office had good things to say about the Glif from Studio Neat, but the only one we had lying around didn’t fit my phone and sat kinda goofy on our tripod plate. So, I did something I wouldn’t have imagined possible a few years ago. I printed a new one.

We got a 3D printer in the office a few months ago. So far it’s been used to make little statues, paperclips, even some chain mail. So I went about designing a new baseplate for our tripod.

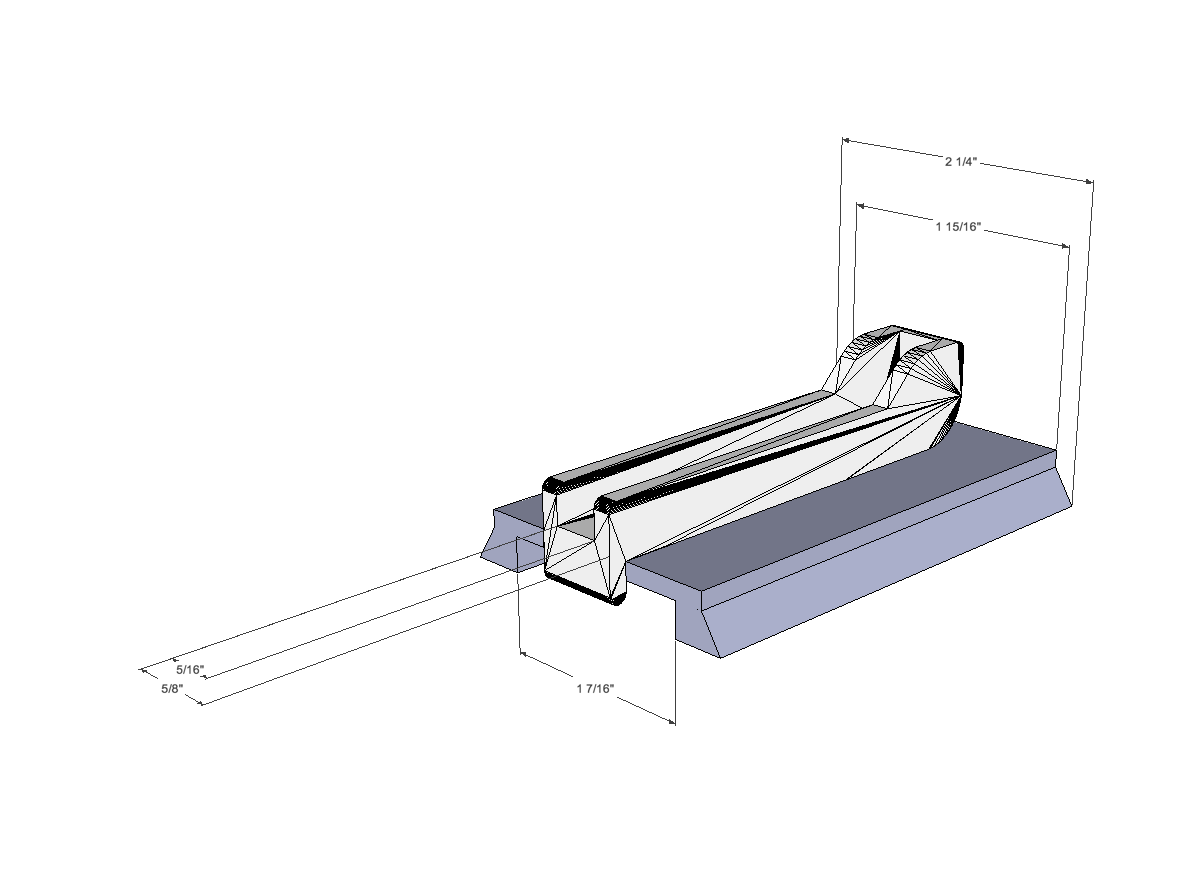

The phone cradle came from an existing design on the wonderful Thingiverse. The base plate itself was just measured from our tripod plate and the whole thing was created with Google SketchUp.

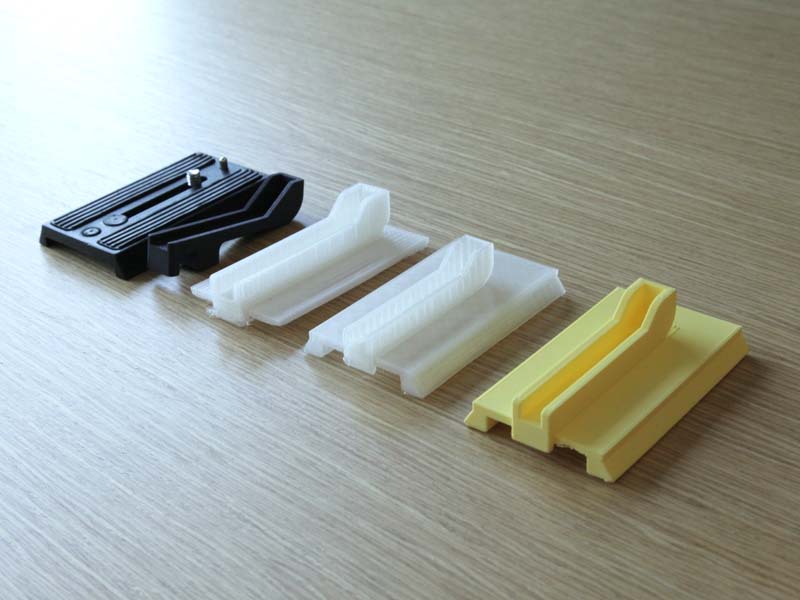

It took a bit of tweaking to get the sizes right and there were a few failed prints where the machine decided to spray plastic filament all over. The final plate, however, is a dream; The phone fits snuggly and the plate stays in the tripod at any angle. You can turn the tripod upside-down and the phone stays secure.

So, if you’re looking for an iPhone 5 mount for a Davis & Sanford FM18 head, go ahead and print one out! You can download the Creative Commons licensed model here.

Jason Green

on 13 May 13Perhaps you can share what printer you use? I’ve been wanting to buy one.

Shaun

on 13 May 13Sure! We’re using the MakerBot Replicator 2.

Justin Jackson

on 13 May 13I’ve had 2 tripods that I had to quit using because I lost the mount piece. Manufacturers often discontinue old tripods, so finding replacement mount pieces was almost impossible.

Printing out new ones would be amazing!

Derick

on 13 May 13@Shaun

How long from start to finish did this take?

Shaun

on 13 May 13I spent about 6 hours total on it. SketchUp isn’t very precise on such a small scale so it was a bit of trial and error as you can see. The final print only takes about 45 min. though.

Tim

on 14 May 13Shaun

You spent an entire day on this?

Why waste that much company time on something so meaningless?

Just buy a new holder, use duck tape to make it stay, etc – anything other than waste an entire day on something like this.

Stephen

on 14 May 13luv the creativity whatever the beans lost

luv to see your next project too bet there will be a lot more beans left over

creativity comes from not counting at first not the other way around

Michael

on 14 May 13That’s neat, Shaun. It’s projects like this that take me one step closer to having an app that lets me photograph a room, a drawer or a closet and then orders or makes everything that should be in it.

Don Schenck

on 14 May 13@Tim You’re not “getting it”. It’s not about the time, it’s about the experience and what it brings long term.

Derek

on 14 May 13Nice

Mike Papageorge

on 14 May 13@Tim

Sometimes it is about the path, the learning and the experience. Upon this we build…

Tim

on 14 May 13@Don, @Mike

People who spend an entire day on creating a new mounting harness, while at work, for their iPhone

1. Are wasting time and not working in more important tasks, or

2. Don’t have enough work in the first place which allows them this much free time, and/or

3. Aren’t bring creative enough in the first place to “Jerry-rig” a mount to work in just a minute or two with tape.

Also, Shaun never explains why he’s even using an iPhone in the first place. Why isn’t he using the camera the tripod was designed for?

Don Schenck

on 14 May 13@Tim—Ever take the long way home??

I either just won, or I feel very sorry for you. :)

Benjy

on 14 May 13@Tim, Shaun is their videographer… researching, acquiring, biulding the tools of his trade are part of his job it’d seem. And having a perfect tool that’s reusable time and time again would seem preferable to re-creating a jerry-rigged solution on multiple occassions.

And if you’ve ever read this blog, you’d understand that the learning for learning’s sake is a highly valued skill at 37 Signals, that may pay dividends in countless ways… whether something direct like a new product or simply an exposure to a new and developing ecosystem that may apply to the business down the road.

Ed

on 14 May 13@Don—I think Tim’s main issue here is the use of company time to complete a 6 hour task that (as far as we’re aware at this point) isn’t directly befitting the company.

When you take the long way home, you don’t leave work earlier to do so, do you? You don’t use company time to take the long way home, you use your own – that’s the key point here, I feel.

Don Schenck

on 14 May 13Understand, and I apologize to you, @Tim, if I came across as arrogant. I tend that way :)

My point is that there’s more to work and life than efficiency and short-term gain. Learning something for the sake of learning something often pays off in the future.

And, @Ed, I sometimes do leave work early and take the long way home. They pay me for my value, not my time. They stop doing that and I’ll go elsewhere. Life is way too short; Don’t miss the fun along the way.

Eric Anderson

on 14 May 13If 37 Signals didn’t want him to use company time to make stuff with a 3d printer I don’t think they would have purchased one. It is my guess that they are well aware of how he is spending his time and feel it is in line with their goals. Their endorsement of workplace experiments shows this is the type of thing they support (in moderation).

Bryan Sebastian

on 14 May 13Shaun, thanks for sharing this. I have heard about 3D printing in passing, but personally had not heard any stories of someone actually using one until now. The only bad thing about this post is now I want a 3D printer :)

Devan

on 14 May 13LOL at all the corporate drones who feel that every minute in the office has to be spent doing “real work”. I wonder if they notated on their mandatory timesheets that they commented on 37s today.

Look deeper – why would a web services company like 37signals even NEED a 3D printer in their office? That they do points to the fact that they think outside the box and want their staff to explore creativity in other forms rather than just cutting web code.

Caleb Mellas

on 15 May 13Great work Shaun! It’s great to see web guys who are using their creative skill to build new products and solve problems. So often we compartmentalize our skills and think we can only do web work. It always excites me to see people doing web, photo, video and products at the same time.

btw what camera were those product shots taken with?

nick

on 15 May 13shaun, are you using a double-extruder (Replicator 2X)? otherwise, how were you able to print the overhang/bridge part of the tripod connector?

Shaun

on 15 May 13@Caleb I shot those quickly with the Canon 5D II.

@Nick we just have the single-extruder Replicator. The ReplicatorG software has settings which allow you to print “supports” in your models. It makes a flimsy scaffold to support any overhangs, which can be easily torn away after the print is complete.

GeeIWonder

on 15 May 13You can turn the tripod upside-down and the phone stays secure.

I like the post but, since this is a designy blog—why would you want to do this?

Bill McNeely

on 16 May 13Shawn,

Your post was timely.

I have had several people tell me I need to make a video for my crowdfunding project at Repay Vets. http://repayvets.com/campaigns/texas-veteran-lawn-service

I had been told I could use my iPhone to the video. However, I don’t have a tripod and even if I did how would I fit my iPhone 4S on it. You answered my problem.

Would your mount work for my iPhone as well?

What tripod do you recommend?

Bill

nick

on 16 May 13@shaun, thats fantastic! i was unaware i could do this with a single extruder.

Frank

on 18 May 13I can’t believe we are already that far ahead… I think that in 10 or 20 years we will do the same with food, we won’t have to go to the groceries, we will just print our food. Not sure if it’s a good thing or not, but i think i’ll live long enough to see it :)

Frank – Mokish

nick

on 20 May 13@Frank ...already on the way. http://www.dezeen.com/2013/03/27/food-is-the-next-frontier-of-3d-printing-janne-kytannen/

This discussion is closed.